Contact

Schlatter Industries AG

Brandstrasse 24 | 8952 Schlieren

Switzerland

+41 44 732 71 11

infoschlattergroup.com

Hans A. Schlatter, born in Zurich in 1886 as the son of a master metalworker, first came to work on resistance welding in America, at a time where this was technology was hardly known in Europe.

After returning to Switzerland, he put this knowledge to good use. His groundbreaking work was well received in the industry and lead to the founding of his company in 1916.

During the First World War, he developed a method for the manufacture of hobnails. This method not only used electric heating to efficiently press and form the nail heads, but also to weld these heads with the pins afterwards. He also used this process of heat creation successfully for spot welding.

In 1930, H. A. Schlatter took over as representative for the wire butt welding machines at the American company Microweld which gained him access to companies and the mesh welding industry worldwide. For example, he provided radio and electric lighting manufacturers with precision spot welding machines, as well as steel manufacturing companies with high efficiency spot welding machines to weld up to 15 mm thick steel panels.

After the Second World War there was significant activity in the European building sector. Numerous new constructions made of concrete needed steel reinforcement. It seemed the obvious choice to weld the reinforcement rods before laying them out as mesh and meant a significant improvement from binding together the individual rods manually. Schlatter seized this opportunity and built his first mesh welding machine. In the beginning, the line wires were welded two by two and one after the other with a cross wire.

The real breakthrough, however, came with the pneumatically driven mesh welding machine. Installing several welding transformers allowed for the line wires to be welded with a cross wire along the whole width of the mesh at the same time.

By the mid 1940s, central heating had become one of the standard amenities in new apartment buildings. Soon Schlatter was offering two solutions for the efficient production of heatingradiators. A further milestone was set at the end of the 1940s. The welding of rail tracks posed a new challenge. The system designed for this process made Schlatter market leader. With the development and the use of flash butt welding, the company has managed to maintain its leading position to this day.

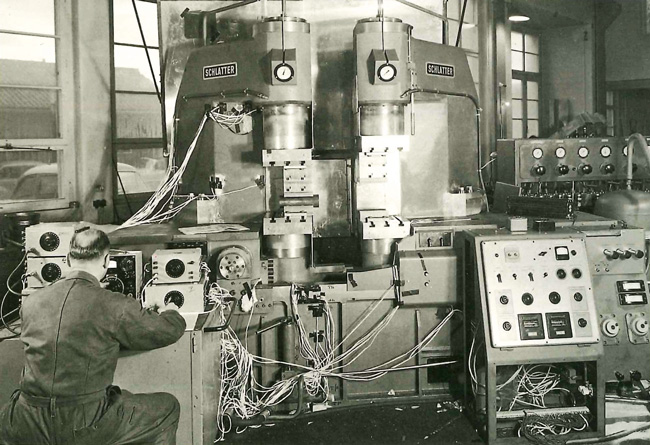

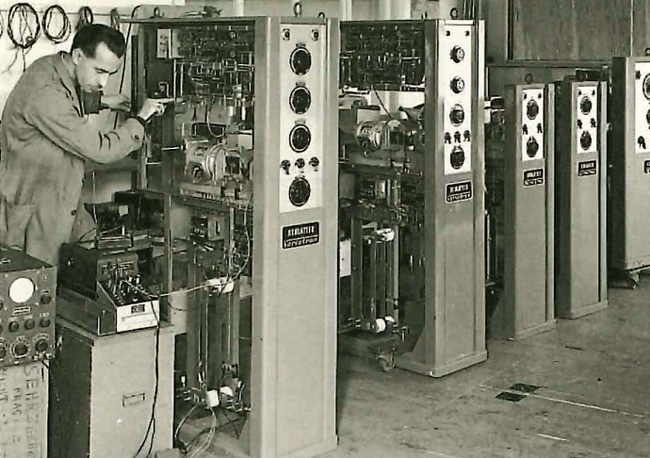

Early on, Schlatter realized that a good machine will only ever become a great one with the right control system. This is why, the company has always placed great emphasis on the in-house development of electrical control systems. Schlatter develops a tube-controlling device that allows for the continuous regulation of the welding electricity. The additional electronic circuit makes it possible to distribute the single-phase loads inertia-free to all three phases. The Schlatter “Synotron”- load equalizer was born.

Through intensive development in the 1940s and 1950s, Schlatter managed to introduce several new products to the market. In the following years, Schlatter focused particularly on providing the latest technology in order to expand the market position. The leaps in the development of control and power electronics opened up new perspectives in achieving this. Schlatter was the first company to introduce rectifier welding machines to the markets.

Once again, Schlatter proved their exceptional quality in the ability to provide comprehensive solutions by developing control systems in-house. Using the latest microprocessor technology in high-tech devices to control, regulation, measure and monitor welding processes guarantees the required quality of the bond. Furthermore, the use of IT opens up new and nearly endless possibilities. Thanks to their usage in processing systems in managing and networking production plants, flexibility, productivity and reliability can be improved considerably.

The continuous development towards becoming an engineering company for complex system solutions requires a clear focus. Right from the start, Schlatter’s key to success was uniting mechanical engineers, welding experts, electricians and software specialists under one roof. From this emerged Schlatter’s three core competences, welding technology, mechatronics and system technology.

The continuous commitment to quality, which holds a key position in the company’s policy, is why Schlatter is ahead of its field.

The incorporation of the Jäger company, which was founded in 1867, opened new doors for Schlatter into the field of weaving. Under the Jäger brand, Schlatter now also offers weaving and finishing machines for paper machine clothing as well as for wire and mesh.

Founded in 1916, Schlatter has developed from being a single plant manufacturer to becoming a solution provider for resistance welding and weaving systems. Decades of independent development activity and expertise in automating production systems provide the basis on which are able to offer our customers the best in sophisticated technology and efficient solutions.

Brandstrasse 24 | 8952 Schlieren

Switzerland

+41 44 732 71 11

infoschlattergroup.com