Contact

Schlatter Industries AG

Brandstrasse 24 | 8952 Schlieren

Switzerland

+41 44 732 71 11

infoschlattergroup.com

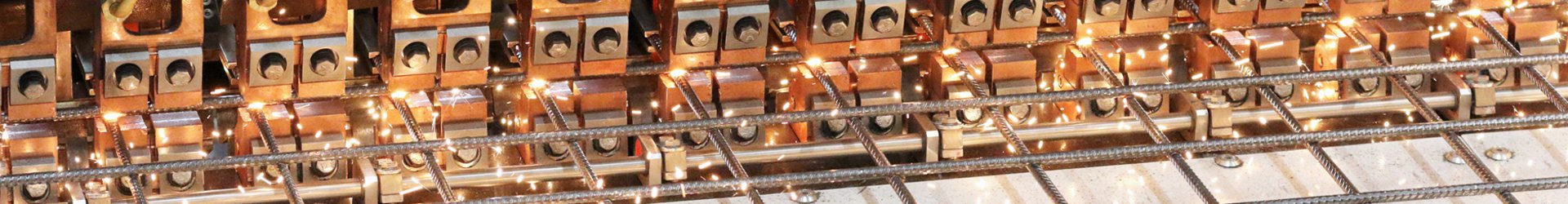

The right concept for individual requirements: The modular structure of the Schlatter welding systems lets you start with minimum investment costs before converting and further extending your plant in line with requirements.

Brandstrasse 24 | 8952 Schlieren

Switzerland

+41 44 732 71 11

infoschlattergroup.com

In the reinforcing mesh sector, the Schlatter Group specializes in the construction of plants for the efficient production of simple and complex reinforcement steel mesh of different shapes and sizes.

In the industrial and fencing mesh segment, the Schlatter Group specializes in the construction of plants for the efficient production of industrial and fencing mesh in small and large lot sizes.

Wire butt welding devices for wire diameter from 0.3 to 16.0 mm.

In the product area rails, the Schlatter Group manufactures stationary and mobile rail welding systems.

Schlatter offers a wide range of extra modules. Most of them can be integrated into existing plants.

We stock a special selection of high-quality plants and also single components in our program.